For a few years now, Zara has been one of the stores I frequent when I shop. I’ve been to Zara stores worldwide, from retail stores in Canada, the United States, Hong Kong to England. I knew that it had been and still is a very successful clothing company, but I had never knew the secret to its success. After the supply chain management lecture on Zara, I wanted to explore this topic a little further and see what others had to say about Zara’s business model. I browsed the web for external blogs on Zara and found this blogpost by Bob Ferrari amongst his many on Supply Chain Matters.

Bob Ferrari provides further insight into the operations of Zara. Although economic uncertainty dwells high in Europe, especially with Spain being one of the epicentres of financial concern, Zara has pulled off a 30 percent increase in profits. How? Zara’s growth can be attributed to two main reasons.

1) its broad geographic scope with retail stores opening worldwide

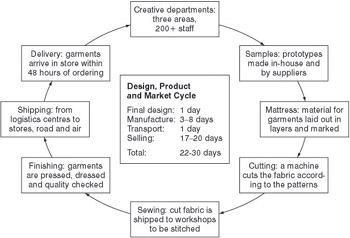

2) its unique supply chain modelled for fast response times catered to adapt to changing consumer tastes.

Zara also boasts a logistics capability of replenishing every retail store twice a week. As if this system was not efficient enough, Zara has decided to build a new state of the art logistics centre involving an investment of 190 million Euros to further set itself apart from competing firms.

Although this supply chain model is extremely hard to replicate, it is interesting to see if any new startup fashion companies will try to follow in Zara’s operational footsteps to success.