What Was Consumed:

2 Plain Mini Bagels – Archer Farms – Target Corp. , Minneapolis

Ingredients: Wheat Flour, Malted Barley Flour, Niacin Reduced Iron, Thiamin mono-nitrate, riboflavin, folic acid, water, cornmeal, dextrose, salt, canola oil, soybean oil, gluten, fermented rye flour, yeast, calcium pro-pronate, sorbic acid.

2 Teaspoons of Butter – Fraser Valley Creamery – Saputo Int. , Montreal

Ingredients: Pasturized milk, salt, colour.

Nectarine – Family Tree Farms, Califronia, USA

Looking Into Bagels

Bagels are a breakfast weakness for many people. But it’s not just the fact that they are high in calories that makes us guilty, it’s the fact that they are a super processed type of bread when you’re buying them at a store pre packaged. And yet, here I am having a bagel for breakfast, so much guilt.

I also want to point out that my bagels were bought in the United States, which means that it is also more likely they needed more oil to produce them. As Manning States,

If the entire world ate just like the USA- humanity would exhaust all global fossil-fuel reserves in just over 7 years.

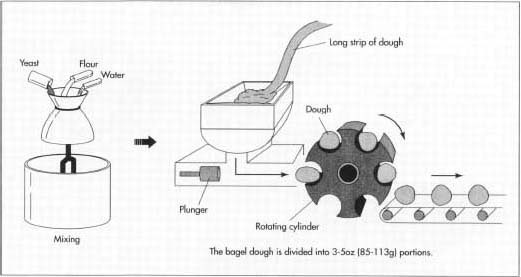

I did some research and found out the process through “How Bagels Are Made” :

To begin the bagel making process, all the ingredients are poured into a large vat machine, which mixes them all together to produce the bagel batter. This machine runs on energy and operate like a giant mixing bowl, allowing them to make enough batter for tons of bagels. After the batter is made, it is either frozen to be kept for later or moved to the next machine. While this is happening, special thermometers keep watch of the bagel batter temperature, to make sure the yeast thrives. In the next machine the dough is separated into portions and then moved forward to a machine that turns it into strips. The strips are then fed into a divider that portions them into single bagel batter portions. The batter then goes into a “Forming machine” that forms the bagels into their special donut shape.

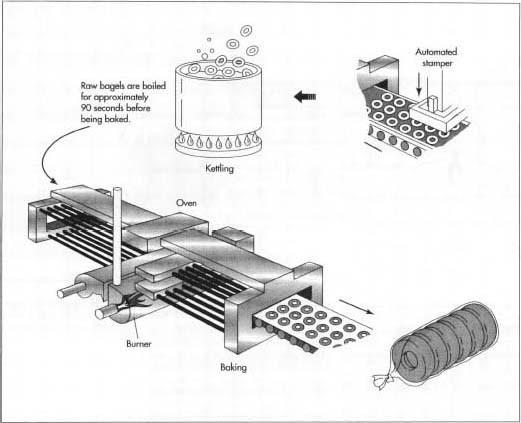

They are then moved into a proofing machine where the yeast is allowed to rise and then quickly cooled. The bagels are then moved into a large boiling machine and boiled until they begin to float. Then they are moved to the oven to be cooked and dried. The bagels then move along a conveyor belt for quality control and into the packaging machine to be packaged and then shipped out. (Look below for the amount of oil it takes to ship the bagels)

As you can see bagels take a lot of energy and oil to make. The bagel making process involves a ton of different machines. This is something I had no idea about. The amount of oil it takes to make bagels is ridiculous but lets not stop there. Let’s also investigate into a couple of the ingredients just to give us a better idea of how much oil is actually in a bagel.

But just in case you think that bagels are the only overly manufactured breakfast food, check out this quote from Manning,

The grinding, milling, wetting, drying, and baking of a breakfast cereal requires about four calories of energy for every calorie of food energy it produces. A two-pound bag of breakfast cereal burns the energy of a half-gallon of gasoline in its making.

Which makes me feel a little less guilty about my bagel, but a little more worried about breakfast in general. Imagine being unable to grab a quick bowl of cereal in the morning because the world doesn’t have enough oil to produce cereal..

Flour

I know that these bagels are made out of a variety of different flours. Wheat, Barley, Rye… etc. The truth is that flour can be made out of most grains and the flour making process if often the same. How each type of grain is cultivated is usually the big difference as different grains need different conditions to grow. For the purpose of this blog posting, I’m going to focus on one grain. The grain that is most commonly used – Wheat.

Wheat is the king of grains, and well deserving of it’s title. As Manning stated:

Wheat was the empire builder; its bare botanical facts dictated

the motion and violence that we know as imperialism.

Wheat was the crop that people wanted to grow and it was popular as it allowed people to make various types of breads and foods. But wheat was not easy to grow and not easy to manufacture into flour. The first step to growing wheat is testing the soil to make sure it’s viable enough to grow the crop. As Manning stated:

Wheat is temperate and prefers plowed-up grasslands. The globe has a

limited stock of temperate grasslands..

Therefore growing wheat is not always the easiest thing to do. To properly grow the wheat it is often necessary to pull up the top soil using heavy machinery that run on gas. Top soil is rich in nutrients and will help the seeds grow better. Unfortunately this is very disturbing to the soil and often leads to quicker erosion. In addition, strong fertilizers must be added to the soil as wheat uses up a lot of the soils resources and requires a lot of them to grow. These fertilizers are heavily infused with nitrogen and oil based minerals.

Wheat takes what it needs.

-Manning

Following the soil preparation, the seeds are sown using a tractor or other seeding machinery (which also use gas). Then the wheat must be well watered as wheat needs lots of water to grow. This is often done using machines as well. Watering continues through all growing seasons. When it is finished growing machines harvest it and ship it off to be eaten by animals or manufactured even further as humans cannot eat plain wheat. This involves gas fueled transport to the flour mill in our case.

At the flour mill, the wheat is inspected and stored. Once the wheat is needed, it is put into several machines and heavily cleaned. A separator, aspirator and then disk separator. The wheat is then washed in warm water and spun dry in a washer-dryer type machine. Take into account that every one of these machines is using energy/oil. The wheat is then moved into two more MACHINES, separated and ground. After grinding, it is moved to another machine and conditioned. It is then put into a giant sieve and separated into flours of different fineness. (How Flour is Made)

Finally bleach agents are added to turn the flour it’s white colour and then the flour is inspected and packaged by a large machine to be shipped out to wherever it needs to go.

As you can see wheat is an oil guzzling crop and a soil eroding crop. In addition, it’s a tough crop that needs to be heavily manufactured in order to be used which adds to the amount of oil it uses.

Vegetable Oil

Vegetable Oil is a very different type of oil than the oil we are measuring in this blog. This oil is often used in foods and it’s completely man made by isolating parts of plants to produce oils. But how does one turn a soybean or stalk of corn into a bottle of oil?

Most vegetable oils are made from seeds and corn germs, the seeds are received by the oil producing plants and cleaned by a machine. Then another machine grinds them so that they are easier to press. On the way to being pressed it is heated to allow the oil to come out easier and then a machine presses the oil out. Then another machine refines the oil to make sure that it is top quality and another machine heats the oil. After being heated it is deodorized and cooled, then packaged by machine. Once the oil is packaged it is ready to ship. (How Cooking Oil Is Made)

Vegetable oil can only be made in large quantities by machines. Without the ability to power machines we would not be able to make enough vegetable oil. This is a scary thought as vegetable oils have become much more popular for cooking than things such as animal fats or butters.

Salt

Salt is a basic seasoning that is used in almost everything. We put it in our meat, our pasta, our soup, and sometimes our drink. We also can use it to preserve foods such as dried meats. Most people are aware that it can come from the sea BUT did you know that salt can also be mined?

According to this article Salt can also be mined from the salt deposits in the layers under the Earth. Mining uses a lot of machines and a lot of oil. Not to mention it is eroding and can be harmful to the environment if habits are turned apart in order to mine on them.

Most of our table salt is mined using this method. Meaning that there is ALOT of oil involved in the creation of salt so that we can add a little bit of flavouring to our food.

How Canadian Butter is Made

Butter is something I absolutely love. I love it in toast, and in my cooking. I love it’s creaminess. I love it so much, that I will cheat on my dairy allergy with it. And when I think of butter, I think of how it was traditionally made- the way my grandparents made it on their farm. Farmers collected their milk from the cows and separated the cream from it. Then the cream was churned by hand until it was well thickened. The remaining liquid was drained and there was your butter! Even though I’m sure there are people in the world who still like to occasionally make some hand churned butter. The process is tiresome and time consuming.

Commercialized butter is made in a very different way. First of all, the cows are milked by energy powered machinery and the milk travels into holding canisters that are then transported (more oil) to where the milk and cream is to be separated and then pasteurized (heated quickly to very high temperatures). The separation and pasteurization machines run on energy – either electric or fuel based energy and require a lot of it. After the cream is separated and pasteurized it is moved to a machine run by MORE energy that beats it into a thick buttery substance. The machine then drains the excess liquid and blends the butter again. After this step the butter is then inspected to make sure it passed regulations and then transported to ANOTHER MACHINE in which it is cut, molded and then wrapped. (How to Make Butter)

The packaged butter is then shipped in a truck to wherever it will be sold.

[See below for amount of oil that uses]

All in all, butter is a really oil and energy consuming thing to make.

California Grown Nectarines

California is known for it’s nectarines as the hot sun allows them to get super juicy and sweet. I love a sweet crisp Nectarine in the morning but I wonder how much oil it costs to make one of those tasty little red spheres.

Nectarines are grown on trees. This particular farm told me when I messaged them that they plant their own trees and often hire people to help plant them as well. Most trees yield a good load of nectarines.

Each tree gets placed 8 to 12 feet apart. In the winter when the trees are sleeping, they prune them and spray them. I assume that oil goes into the manufacturing of the chemical sprays that get applied in the winter as chemicals are often heavily processed and made by machinery. In the spring they are fertilized, and sprayed with fungicide. They use machines to apply the spray to the tree, these run on energy. In addition, fertilizer uses a lot of oil in it’s production process, fertilizers are also heavy on chemicals and can even contain oil in their ingredients. The trees continue to be sprayed in the late spring and early summer. In addition, they are irrigated by machines to give them enough water as Californian summers are quite dry. (How To Grow Nectarines)

Once ready, the nectarines are harvested, put in boxes and shipped off to their intended destinations (See below for how much oil a trip from California to Vancouver costs).

I believe that fruits that grow on trees have the potential to be less oil consuming than produce that grows in the ground but the involvement of heavy fertilizers, and the need to spray them increases the amounts of oil necessary to cultivate them.

I opted for the non-organic Nectarines, but organic nectarines will have a far smaller oil footprint. In addition, Nectarines are one of the fruits that people say you should always try to buy organic as they can be heavily sprayed and absorb chemicals quite easily.

Getting The Food To My Plate

Using Gas Buddy.Com I managed to investigate into how much gas the following trips would use…

Driving the produced and packaged bagels from Minneapolis all the way to Vancouver in a small commercial rasied cab truck would require 200 gallons of gas and would produce over 4000 pounds of carbon emissions. A larger truck would need more gas and produce more carbon.

Driving a small truck of Nectarines from the Family Tree Farm in California to Vancouver would use up approximated 100 gallons of gas and produce more than 2500 pounds of carbon emissions.

Driving a small truck of Fraser Valley butter from Montreal to Vancouver would use approximately 300 gallons of gas, and produce more than 6800 pounds of carbon emissions.

In total to move all 3 parts of my breakfast from their places to my local grocer would use up more than 600 gallons of gas, and emit over 13200 pounds of carbon emissions. WOW. And that’s only in one of the smaller models of commercial trucks.

Since 42 gallons of crude oil produces approximately 19 gallons of gasoline (US Energy Information), that would mean that it would require 1,326 gallons of oil just to drive my breakfast to my table. That is 1, 326 gallons of oil for 379 calories of food. Which converts to.. 3.5 gallons of gas per calorie. Manning stated that:

Every single calorie we eat is backed by at

least a calorie of oil, more like ten.

And it seems he was right.

So throughout the rest of my blog, keep this in mind, TRANSPORTATION USES A LOT OF OIL. THE FURTHER YOUR FOOD IS, THE MORE OIL IT USES.