After releasing the long-awaited iPhone 5S and 5C, Apple ups its supply chain technology to get a leg up on the competition.

The following blog post references a Bloomberg article which outlines the new methods used by Apple:

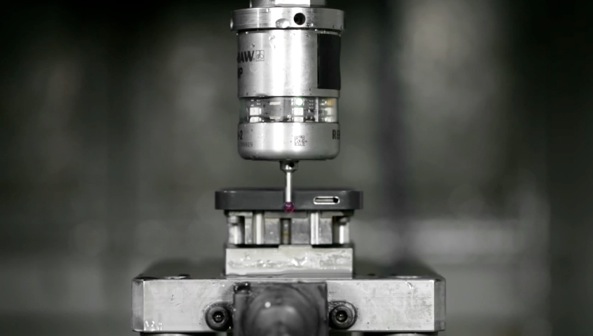

The $10.5 billion dollar investment proves that Apple is serious about improving its supply chain management. The new equipment will polish iPhones, and use laser technology to carve the aluminum body of the MacBook line. In addition, it will also test the camera lens on iPhones.

From a marketing perspective, this makes sense for Apple. The company’s iPhone product line is known to consistently have better build quality than its peers. This is a point of emphasis for consumers like myself when purchasing a phone. Adding new technology to improve the manufacturing process further separates Apple from its closest smartphone competitor, Samsung. Ironically, Samsung has been questioned for putting out smartphones with poor build quality. The new supply chain investment by Apple with further add value to their products since it is more efficient than their previous method and also provides increasingly rigorous testing. This will add to customer satisfaction because there will a lower chance that customers receive a defective product. In turn, this could potentially increase brand loyalty among consumers because they receive well-built phones.