Introduction:

Assignment 1.3 aims to familiarize a non-technical audience with a medium complexity industry term. There will be three types of definitions for the same term: parenthetical definition, sentence definition, and expanded definition. A parenthetical definition is a simple, one sentence explanation that defines the term in parentheses. A sentence definition is a one to two sentence definition of the term that defines it and gives a basic overview. An expanded definition is a multi-paragraph definition that includes multiple expansion strategies to help explain it to the reader. My expanded definition will include the history and etymology of poka-yoke, required conditions, operating principle, negation, and examples.

Parenthetical definition:

Poka-yoke (mistake or error proofing) is a Japanese term used in lean manufacturing to reduce defects by preventing human error.

Sentence definition:

The Japanese term poka-yoke means mistake-proofing. It is used in lean manufacturing to prevent defects from occurring by eliminating the possibility for human error.

Expanded definition:

Formal sentence definition, history, etymology:

The Japanese term poka-yoke is used in lean manufacturing in an effort to reduce defects or injuries by eliminating the possibility of human error. A process or piece of equipment is poka-yoke if it prevents the operator (“yokeru”) from making mistakes (“poka”). The concept of poka-yoke was formalized by Shigeo Shingo as a part of the Toyota Production System, which is a major precursor to modern lean manufacturing.

Required conditions, operating principle, example:

The term poka-yoke is often referred to its more colloquial term “idiot-proofing”. The concept of poka-yoke means that mistakes should not be simply difficult to make, but impossible. A modern example of poka-yoke is the Saw Stop, an injury prevention mechanism that can be added to a table saw. If someone happens to touch the saw blade with their finger during operation, the Saw Stop immediately and aggressively applies a brake that causes the saw blade to stop rotating and disappear into the table. This makes it impossible for a worker to seriously cut their finger on a running saw blade. Poka-yoke is not only to prevent injury, but also defects and damages. An electrical surge protector can be considered poka-yoke because it protects the appliances it connects to from overloading in event of a voltage spike.

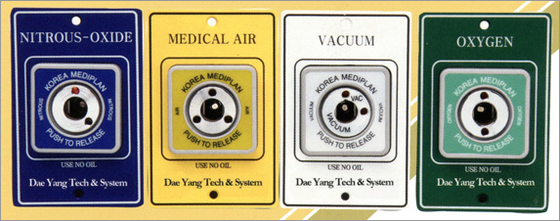

Figure 1: Poka-yoke design of air connectors in a Korean hospital. The unique connectors prevent a hose from being connected to any other port.

Negation, comparison:

Manufacturing engineers must be careful when declaring a system to be poka-yoke as it can be dangerous to declare a machine poka-yoke when it is not. True poka-yoke solutions differ from common injury or defect prevention methods if those methods still allow the possibility of making mistakes. There was a case described in a machine guarding assessment by the Manufacturing Safety Alliance of British Columbia where a worker was operating a press that required him to push a piece of metal into a machine, and then simultaneously press two buttons spaced a few feet apart to stamp the piece. The worker grew tired of moving his hands back and forth between the workpiece and the buttons and decided to instead keep both hands on the buttons and push the workpiece into the machine with his nose. Predictably, an ambulance had to be called after he operated the machine in this method. The process was declared to be poka-yoke by the designer, but it clearly was not!

References:

“The Technology”. SawStop: America’s #1 Table Saw. SawStop, 2019, http://www.sawstop.com/why-sawstop/the-technology

Luthra, Gurpreet. “POKA YOKE – Applying Mistake Proofing to Software”. A Techie’s Notebook, http://techie-notebook.blogspot.com/2012/07/poka-yoke-applying-mistake-proofing-to.html

“Poka-yoke – Toyota Production System guide.” Toyota: the official blog of Toyota GB”. Toyota, 2016, https://blog.toyota.co.uk/poka-yoke

Leave a Reply