Quaker Oats

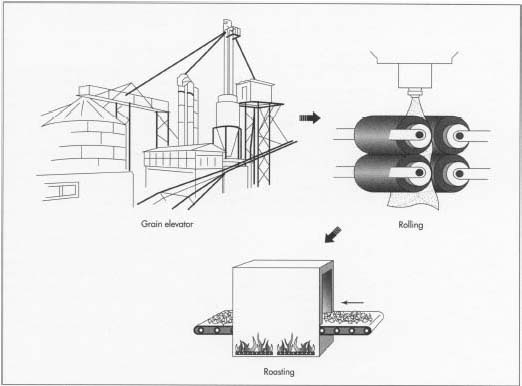

Role in Oil: Oatmeal manufacture involves harvesting, washing, steaming, rolling, cutting roasting, packaging and hulling the oats. `Ventilation systems that reduced spoilage, escalators and endless conveyer belts to move the product to and from the warehouses. All of these steps require oil and energy to run the factory machines.

Delivery: Quaker Oats is an American compant, however there is a factory in Ontario that distributes the oats throughout Canada. The product is transported via delivery truck.

Vancouver BC to Peterborough Ontario-4500km. aprox.

Packaging: According to the claims on the website , Quaker Oat products have reverted to use recycled paper board. The company used to package their products in large tin cans.

Multimedia: Small steps from the Quaker company.

George Cormack, an employee at Quaker Oats Company, designed a number of laborsaving devices.